How to Measure Your Roof

In order to manufacture sheets to your specification we will need accurate measurements for your roof. Sometimes confusion arises when supplying this information. Please see below for a brief explanation of these terms.

Common measuring terms

Pitch

The roof pitch is the angle of the slope of the roof. This is used to calculate flashing angles at the ridge and eaves.

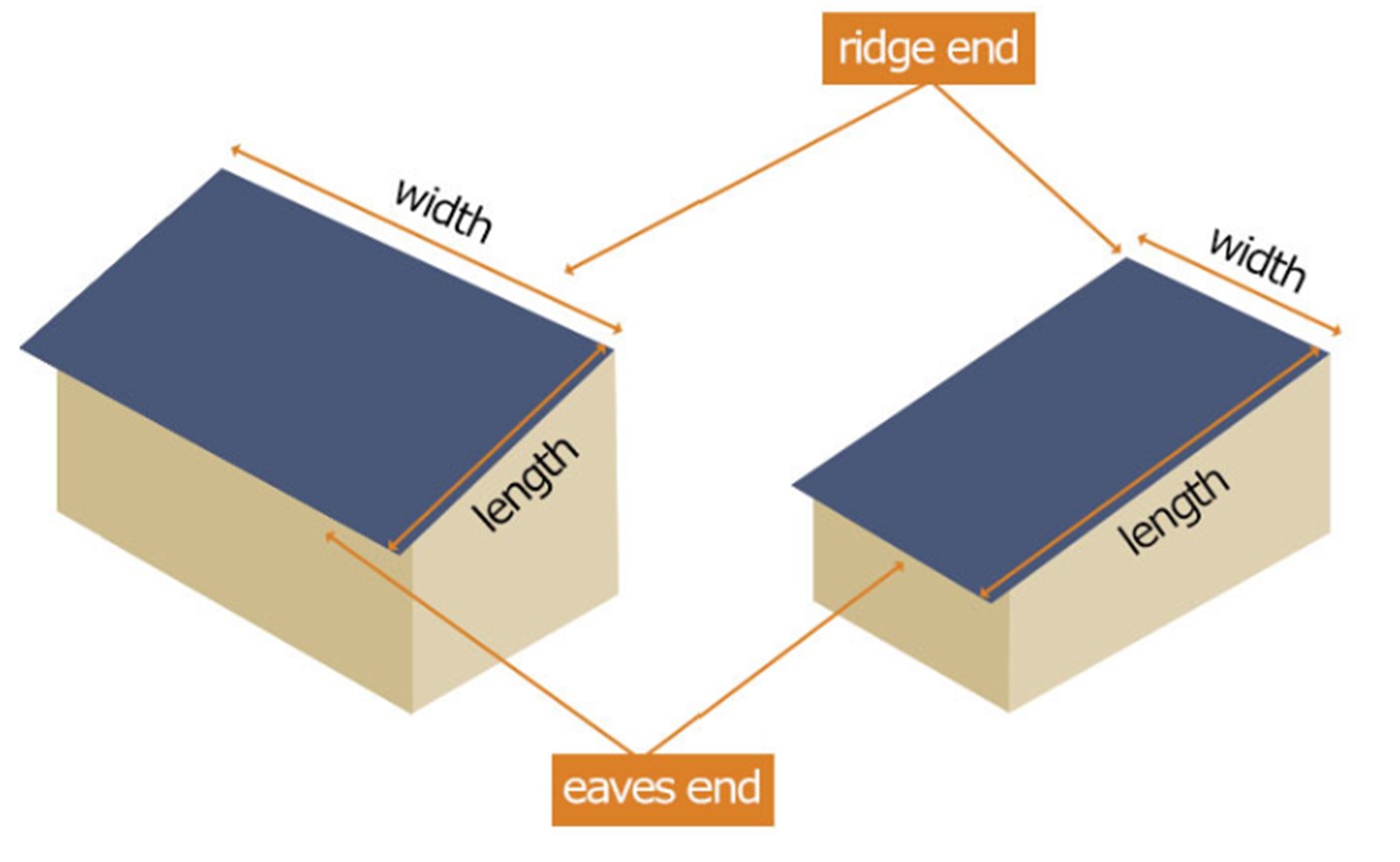

Mono pitch roofs

Width

When calculating roof cladding the width measurement will refer to the direction of lay. This allow us to calculate the number of sheets required based on the cover width of each sheet.

Length

The length will refer to the length of each sheet. This will correspond to the fall or the distance the water with travel from ridge to eaves. Always remember to include an overhang of around 50mm to 100mm to allow water to run off. Sometimes the width and length may seem the wrong way round. (e.g. The width of the roof may be more than the length of the sheets) It is very important that the correct measurements are supplied to ensure your roof sheets are manufactured correctly.

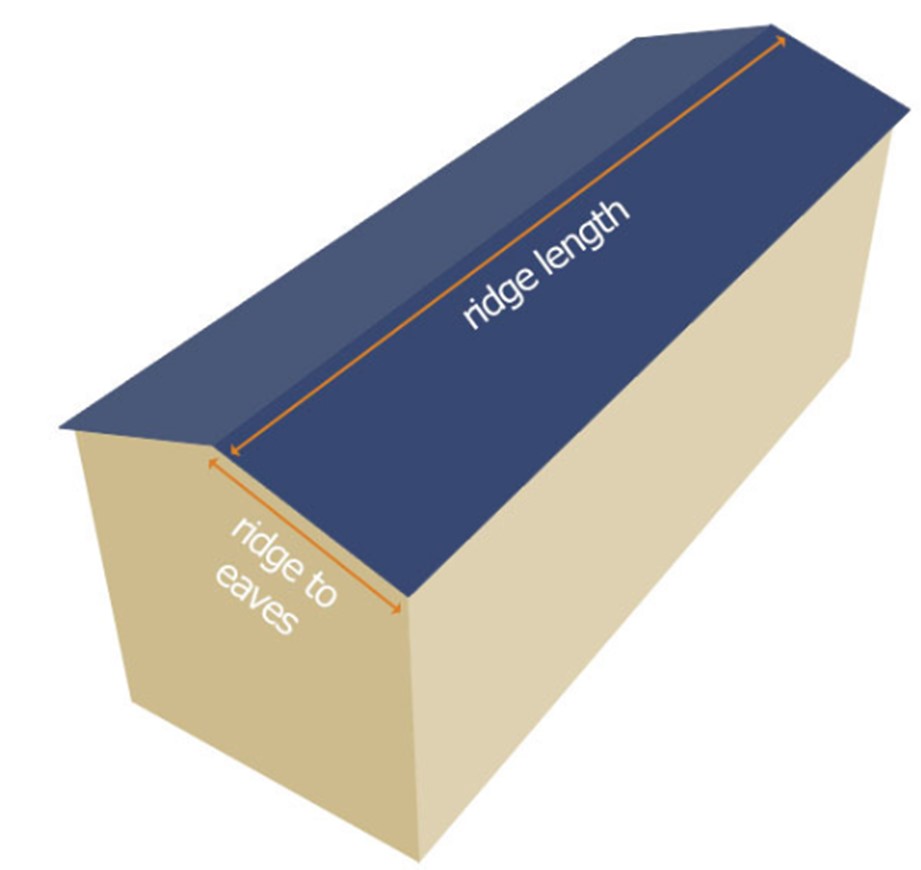

Apex roofs

Ridge length

Similar to the width measurement on mono pitch the length of ridge is required to determine the amount of sheets required each side of the roof.

Ridge to eaves measurement

The ridge to eaves measurement will determine the length of the sheets required. A gap of approx. 50mm should be left at the ridge (or tip of the apex) as sheets from both sides should not be touching. Also an overhang at the eaves (or gutter end) for water to run off should be accounted for.

Different types of roof

Mono pitch (single slope)

Mono pitch roofs are very common in garages and car ports. Sometimes the width of a mono pitch roof is more than the length of the sheets required. The examples below gives guidance on the measurements that should be taken to correctly specify your roofing sheets.

Mono pitch roofs are usually the easiest to measure. A width measurement is required to calculate the number of sheets. The length measurement is required to calculate the length of sheets. Flashings can be used at the ridge end and sides if required. They types of flashing can differ depending on situation.

Apex (double slope)

Apex roofs are usually even sided but can be uneven (sheet lengths will differ from one side to the other). The diagram below gives guidance on the measurements that should be taken to correctly specify your roofing sheets.

The ridge length is used to calculate the number of sheets required for each side. The ridge to eaves measurement is used to calculate the sheet lengths. If the apex is uneven ridge to eaves will need to be taken on both sides.

Quick Tip: When measuring your roof always measure in more than one place to ensure your roof is in square. If you find you have differing measurements always order your sheets to the longest length.

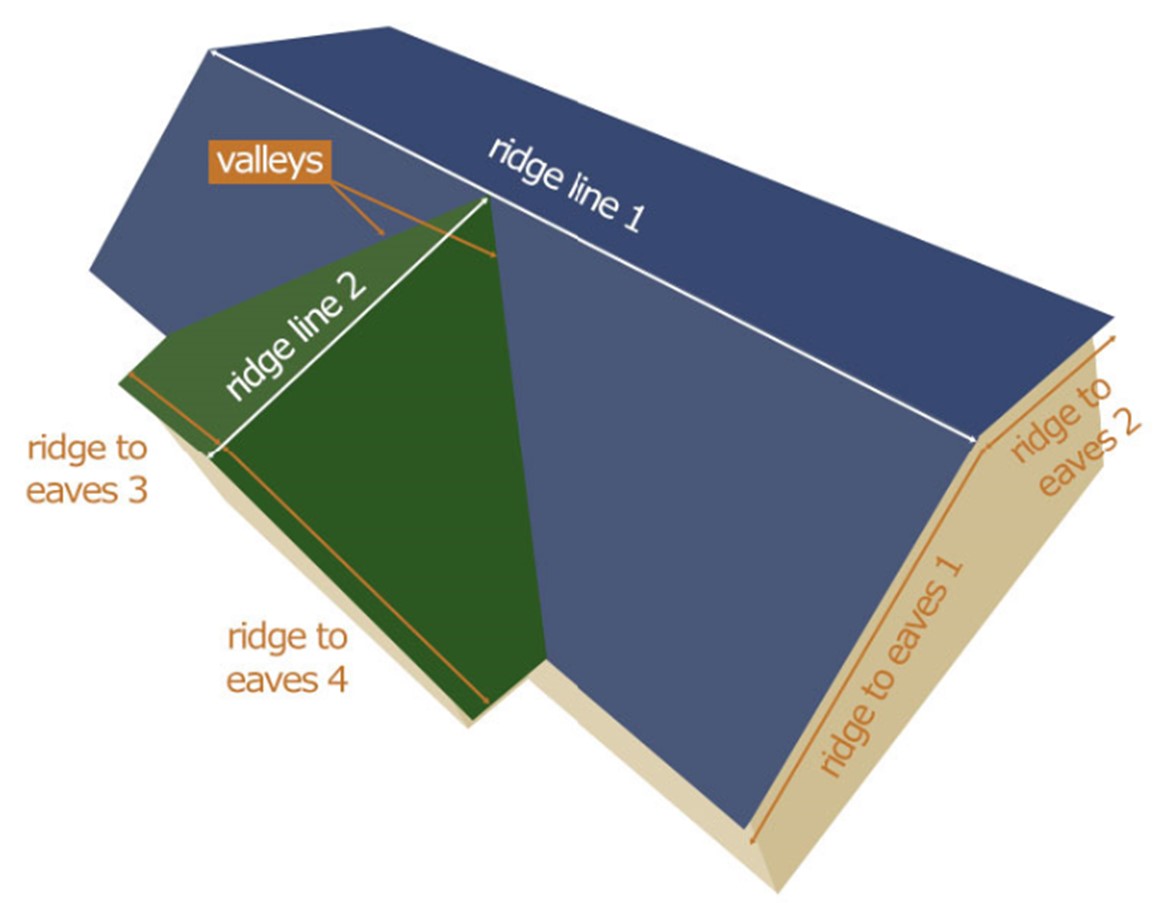

Adjoining apex

Adjoining apex roofs incorporate more than one apex roof connected to each other. Measurements on these roofs need to be taken a little differently from an ordinary apex roof. Sheets will need to be cut on site where the roofs join and valley or hip flashing should be fitted at the joins. The following examples give guidance on the measurements that should be taken to correctly specify your roofing sheets.

Example 1 T-shaped

The below example is a common form of an adjoining apex roof commonly known as T-Shaped. The joins form two valleys which will require flashing.

Measurements are essentially taken as two roofs (indicated above in blue and green)

To calculate the sheets required for the main apex (blue) ridge line 1 must be taken to calculate the number of sheets required whilst ridge to eaves 1 and 2 are used for the sheet lengths each side of the apex.

The process is then repeated for apex 2 (green) using ridge line 2 and ridge to eaves 3 and 4.

Sheets are cut down on site to create the valleys. Two piece valley gutter flashings are recommended to divert water away and provide a neat finish where sheets meet at the valley. Ridge flashings are used at the ridge lines (tip of the apex). Bargeboards can be used along the gable ends.

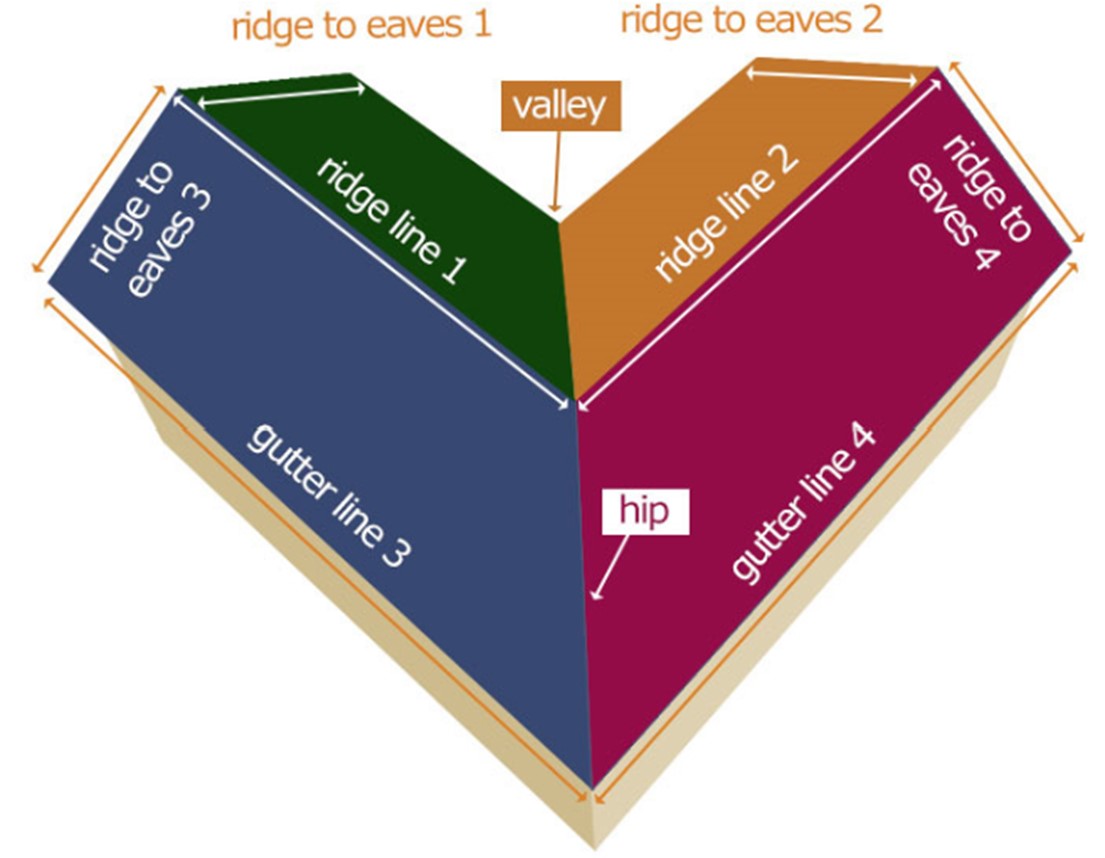

Example 2 L-shaped

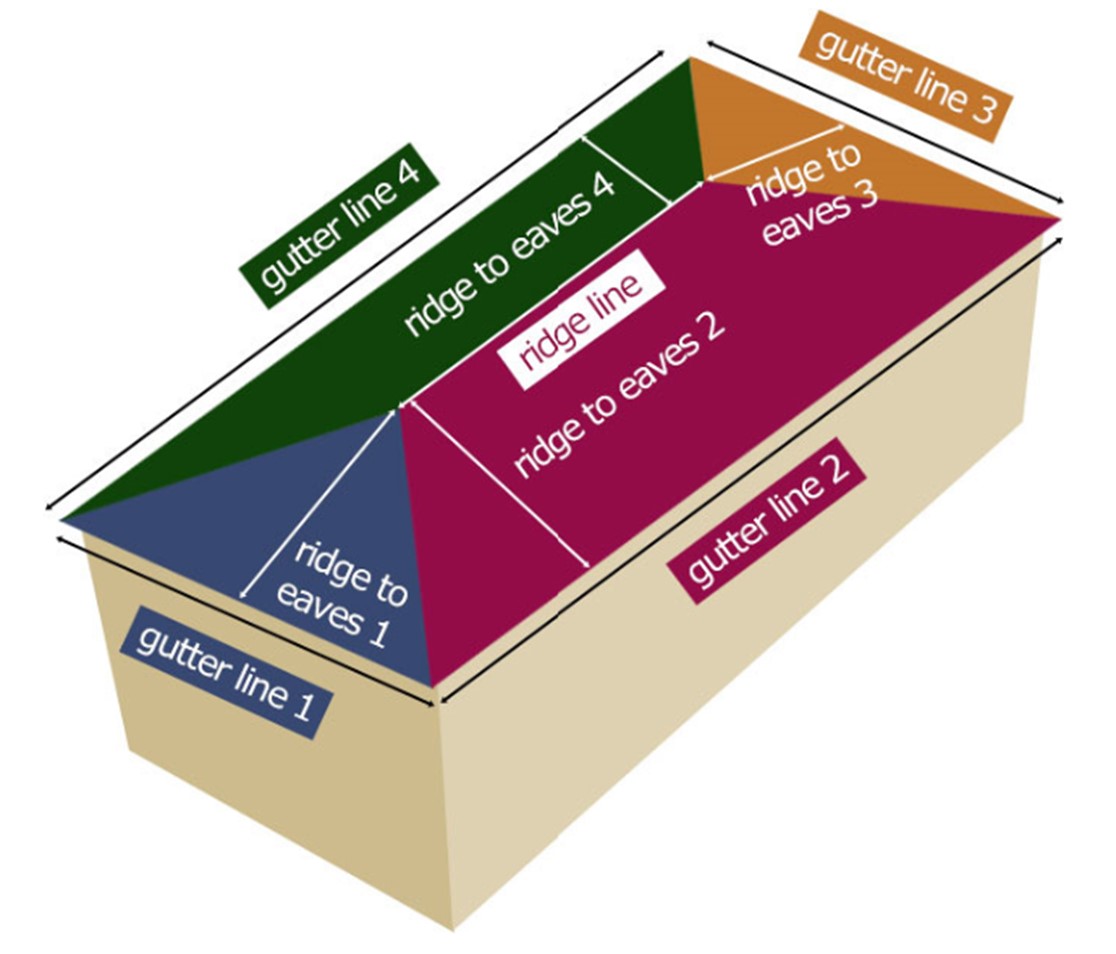

The above example is slightly more complex than the T-shaped roof and should essentially be treated as four separate areas.

To calculate sheets requirements measurements must be taken along ridge line 1 and ridge to eaves 1. This process should then be repeated for ridge line 2 and ridge to eaves 2. This will give you sheet size specification for the inside section of the L-shaped roof (green and orange areas)

You can then move onto the outside section (blue and purple) Measurements should be taken from gutter line 3 and ridge to eaves 36 followed by gutter line 4 and ridge to eaves 4.

The above example forms a valley on the inside and a hip on the outside. Two piece valley flashings and hip flashings should be used where sheets meet at the valley and hip. Ridge flashings are used at the ridge line (tip of the apex). Bargeboards can be used along the gable ends.

Hipped

Hipped roofs will require cladding at the gable ends as well as the two sides of the apex. This will mean that four areas will require cladding. Measurements on these roofs need to be taken a little differently from an ordinary apex roof. Sheets will need to be cut on site where each cladded area meets and hip flashing should be fitted at these joins. The diagram below gives guidance on the measurements that should be taken to correctly specify your roofing sheets.

Hipped roofs require four sections of cladding (indicated above as blue, green, purple and orange areas). Measurements must be taken along the gutter line for all four sections as well as ridge to eaves.

Hip flashings are should be used where sheets meet. The amount of hip flashing is calculated by measuring each separate hip join.

Ridge flashings are used at the ridge line (tip of the apex). The amount of ridge flashing is calculated by measuring the ridge line.

Safety

Working with steel and on roofs can be hazardous. Safety precautions, including the wearing of P.P.E. (Cut resistant gloves, clothing, footwear and a Hard Hat) is highly recommended.

Crawling boards should be used while working on a roof to keep your weight evenly distributed and minimise the risk of damage to the roofing sheets.

Employers and self-employed contractors are required by UK Law to carry out a risk assessment before the commencing of any roofing work. More information on this can be found on the Health and Safety Executives website www.hse.gov.uk

If you are unsure about how best to measure your roof, we would recommend contacting an experienced builder/roofer.