Understanding Anti-Condensation Liners

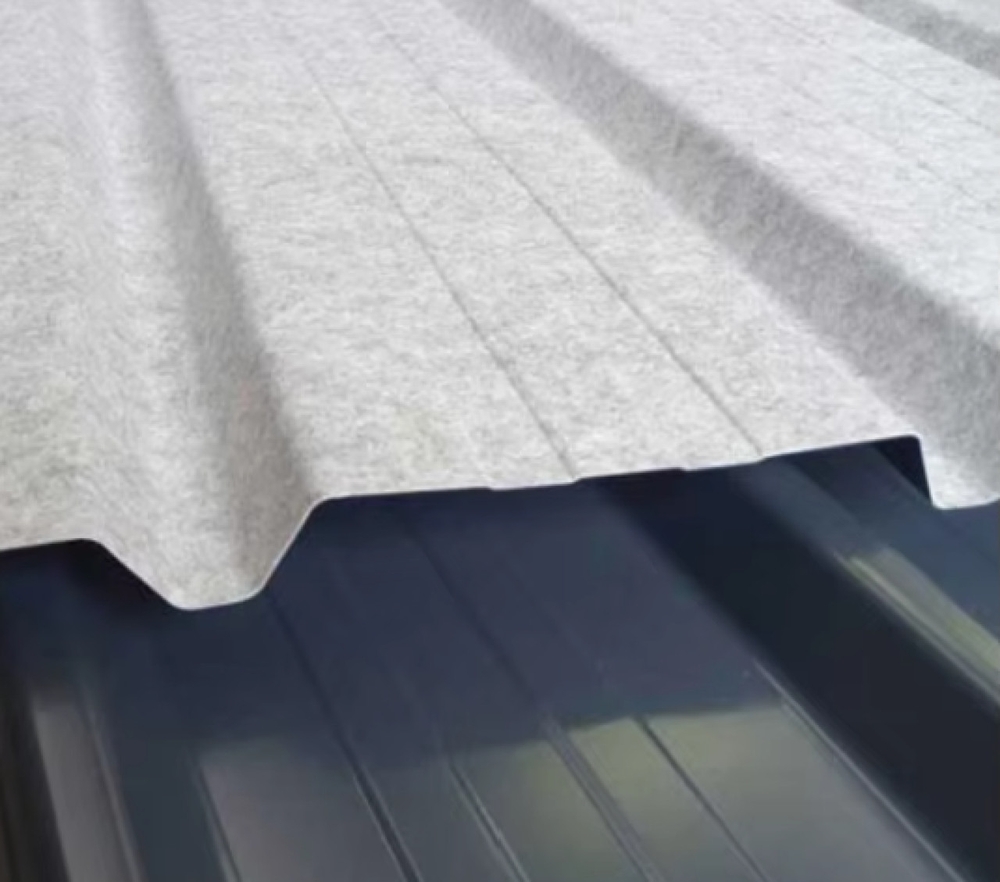

An effective, cost-efficient solution for reducing condensation in buildings is the anti-condensation liner. By applying a flock material to the underside of box profile and corrugated roofing sheets, the likelihood of condensation is minimized, offering a more affordable alternative to fully insulated panels.

Important Note: For the anti-condensation liner to function properly, adequate airflow is essential. The water absorbed by the liner needs to evaporate, so it's crucial to ensure ventilation around the sheets. We suggest leaving the eaves and ridges open, but if foam fillers are used, they should be notched for ventilation or replaced with mesh-ventilated versions. The minimum recommended pitch for roofs using this liner is 10° for optimal performance.

If a roof lacks sufficient ventilation or has an inadequate pitch, the liner may retain excessive moisture, potentially causing drips, especially in cold weather conditions, such as early mornings.

Check out the video below to see a comparison of the condensation effects on steel sheets with and without an anti-condensation liner.

Cost-Effective Solution to Condensation Issues

In buildings where condensation is a concern, adding an anti-condensation liner to roofing sheets offers a budget-friendly approach. For maximum effectiveness in managing condensation, we highly recommend the DripStop anti-condensation liner.

How Condensation Forms and How to Control It

Condensation occurs when the temperature and humidity inside a building reach the dew point, causing moisture to form on the underside of uninsulated metal roofing. If condensation is excessive, water droplets will form and begin to fall. The traditional way to address this problem is by installing roof insulation to prevent the metal sheet from reaching the dew point temperature.

DripStop anti-condensation liners provide a more economical solution compared to complete roof insulation, effectively managing condensation at a lower cost.

Benefits of Anti-Condensation Lined Sheets

- Cost Savings: Save up to 25% compared to traditional insulation methods.

- Durability: DripStop liners are resistant to ripping, tearing, and deterioration, unlike standard insulation and vapor barriers.

- Easy Maintenance: The liners can be cleaned easily with a hose or pressure washer.

How DripStop Works

The DripStop anti-condensation liner consists of a self-adhesive felt material applied directly to the sheets during the roll forming process. This allows the sheets to arrive pre-linered and ready for immediate installation. DripStop traps moisture in specially designed pockets within the membrane until conditions drop below the dew point. At this point, the moisture is gradually released back into the air as normal humidity.

DripStop provides a practical, cost-effective way to address condensation issues without the expense of full roof insulation.