Item Specifics

Finish: Galvanised

Galvanised sheeting is a high quality hot dipped zinc coated steel with no additional finishes added. Now the base material for Polyester paint and PVC Plastisol coated roofing sheets, galvanised steel sheets have been used for over 100 years.

It is worth noting that galvanised steel will weather over time and become duller. Also galvanised steel can vary in finish and we highly recommend taking a coated sheet if colour is an issue.

As long as the material is fitted and treated properly then it can last a number of years, however the material is very susceptible to corrosion especially the steel underneath the zinc coating. We do not recommend using galvanised sheets within 3 miles of the coast as coastal environments can significantly decrease lifespan.

Galvanised steel sheets can sometimes be confused with stainless steel, however it is important to note these are different products.

Please be aware that galvanised sheets cannot be painted until they have weathered. This usually takes approx 6 months. If a more durable coloured finish is required please consider polyester painted or PVC plastisol sheets

Galvanised steel is not a colour and surface finish is not consistent. As the steel weathers you will see discolouration in areas. Over time the surface will become rougher as the material weathers. If you require a more consistent finish we would recommend using a coated steel finish such as polyester paint or PVC plastisol.

Care should also be taken when storing galvanised sheets. We recommend storing indoors at a consistent temperature to avoid water ingress and weathering whilst still stacked. Also degreasing the sheets is recommended to remove any excess rolling oil as this may cause reactions when the steel begins to weather.

Finish Properties

| Property | Unit | Value | Test Standard |

|---|---|---|---|

| Standard zinc coating | (g/m2) | 275 (Z275) | |

| Minimum yield stress | (N/mm2) | 220 (S220GD) | EN 10147:2000 |

| Bending and profiling quality | DX51D | EN 10142:2000 | |

| Estimated time to first maintenance*: | |||

| Dry and unpolluted | (years) | 20-50 | |

| Suburban and rural | (years) | 5-10 | |

| Industrial and urban | (years) | 2-5 | |

| Coastal | (years) | 1-5 | |

| Fire classification | A1 | BS EN 13501 |

Product Details

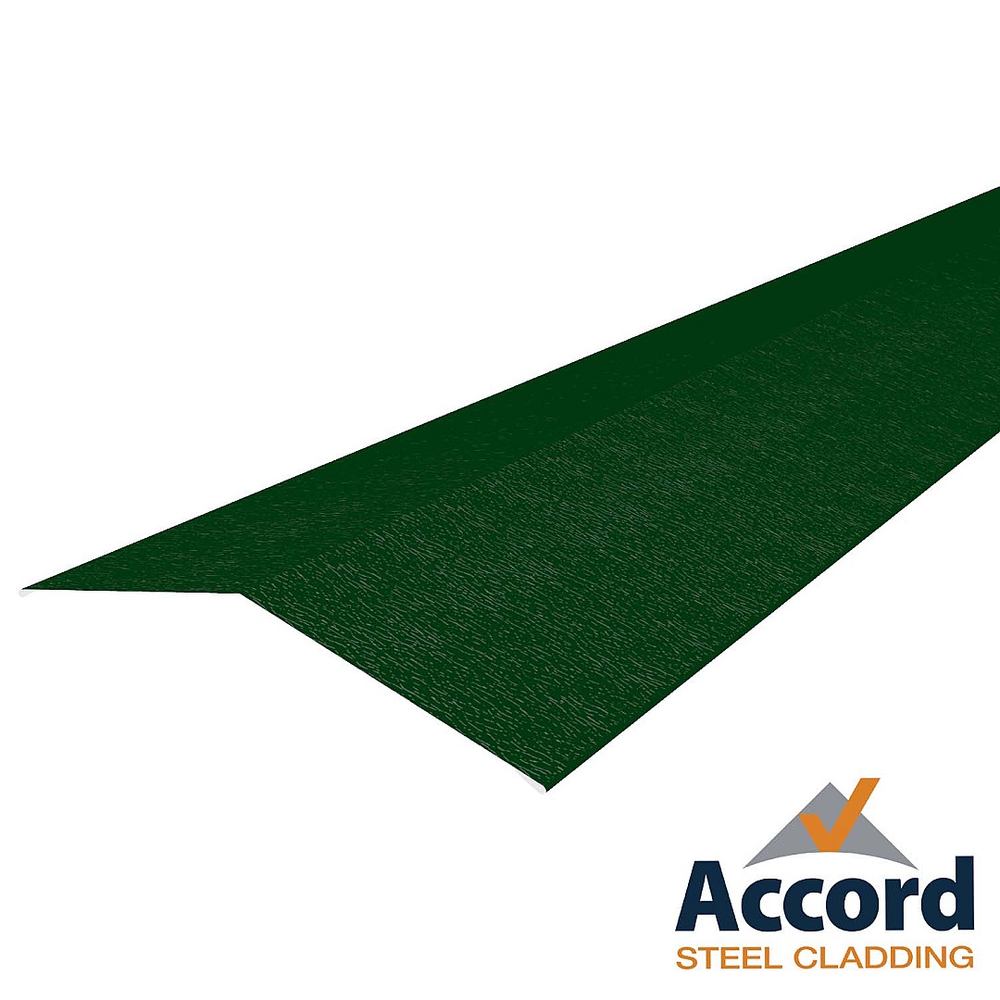

Ridge Flashings – for Pitched Roofs

Our steel ridge flashings are manufactured in 3 metre lengths as standard and tailored to suit your roof pitch. Available in a wide range of finishes and profiles, these flashings provide a durable, weatherproof seal at the roof apex—ideal for agricultural, industrial, and commercial buildings.

Standard Specification

- Length: 3.000m (Other lengths available on request)

- Wing Size: 200mm standard (custom sizes available)

- Profile Options: Standard 'v' shape, Flat Top, Roll Top, Diamond Ridge, Rolltop Diamond Ridge

- Pitch Compatibility: Made to suit your roof pitch

Available Finishes

- Galvanised Steel

- Polyester Paint

- PVC Plastisol

- Granite® HDX

- Spectrum®

- XL Forte®

- Aluminium

- Rust Effect

Applications

- Ridge capping for pitched metal roofs

- Weatherproofing agricultural and industrial buildings

- Custom flashing for restoration and retrofit projects

- Architectural detailing with premium finishes

Whether you need a traditional galvanised roll top or a modern rust-effect flat ridge, we can manufacture to your exact pitch and dimensions. Contact us to confirm finish availability, request a quote, or discuss custom sizing.

Please be aware that all folded flashing angles are subject to a +/- 1° and section dimensions are subject to tolerances of +/- 1.5mm