Kingspan QuadCore Insulated Composite Roof Panels (KS1000RW)

Kingspan QuadCore Insulated Composite Roof Panels (KS1000RW)

Order Online

| Quantity | Length ?Total length of the top sheet of steel. The steel liner and insulation will be shorter by the size of the cutback. | Unit | Cutback (mm) ?Typical Values: Overhang: 75mm Endlap: 150mm Minimum: 20mm Maximum: 300mm | Overlap ?As viewed from the gutter end of the sheets. | |

|---|---|---|---|---|---|

Item Specifics

Profile: Kingspan KS1000RW Composite Panels

Profile Information

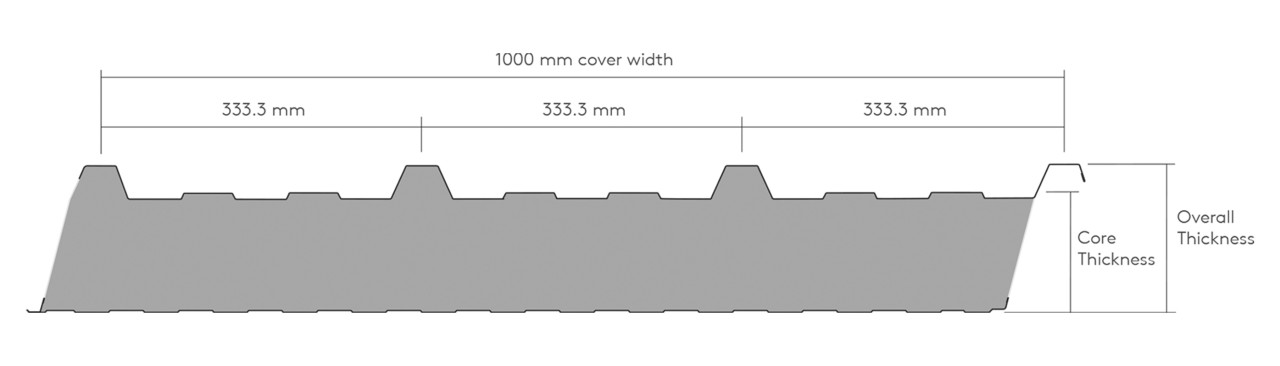

| Cover Width | 1.000m |

| Minimum Length | 1.800m |

| Maximum Length | 12.200m |

| Minimum Pitch | 4° |

Finish: XL Forte

Product Details

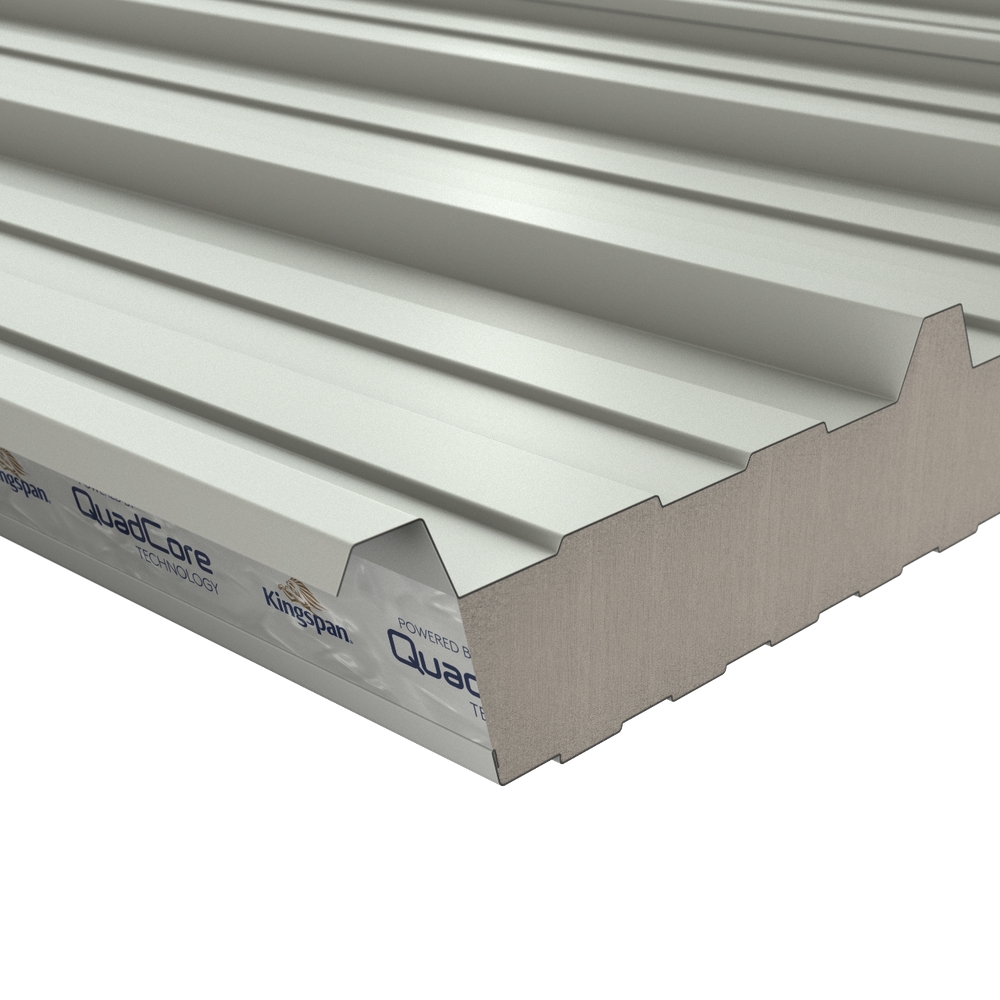

Kingspan KS1000RW – QuadCore Insulated Composite Roof Panels

The Kingspan KS1000RW is a high-performance insulated roof and wall panel system featuring Kingspan’s advanced QuadCore® technology. Designed for pitched roofs, it combines thermal efficiency, fire safety, and fast installation in a single composite sheet.

Product Specifications

- Core: QuadCore® insulation

- Core Thickness: 40mm - 150mm

- Panel Width: 1000mm (cover width)

- Length Range: Cut to size from 1.8m to 14.5m (standard); longer lengths up to 29.3m and shorter under 1.8m available on request with extra charges.

- External Finish: Steel with various coatings (e.g. XL Forte, Sectrum)

- Internal Liner: Standard white or custom finishes

- Fire Rating: Euroclass A (EN 13501-1)

- Thermal Conductivity: 0.012 W/m·K ( 150mm QuadCore core)

- Application: Pitched roof systems (minimum pitch: 4°) and Walls

Key Features

- QuadCore® insulation for superior thermal and fire performance

- Factory-engineered composite panel for fast, consistent installation

- Suitable for industrial, commercial, agricultural, and domestic buildings

- Available in a range of colours, coatings, and liner options

- Compatible with daylighting, ventilation, and edge detailing systems

- Integrates with Insulated FAIRS Factory rooflights

Applications

The KS1000RW is a through-fix trapezoidal profiled insulated roof panel which can be used for building applications with roof pitches of 4° or more after deflection.

- Warehouses and logistics centres

- Manufacturing and processing facilities

- Farm buildings and cold stores

- Retail units and showrooms

- Residential extensions and outbuildings

Kingspan KS1000RW panels are stocked in popular finishes and can be cut to your required length. Contact us for lead times, colour options, or to request a technical datasheet.

Advantages of composite panels

Composite roof and wall cladding offer you significant advantages over conventional site assembled systems, such as:

- Fast, single fix installation

- Reliable thermal performance

- Insulation continuity

- Minimal air leakage

- Elimination of cavity condensation and cold bridging

Available Lengths

Standard Lengths 1.8 – 14.5m

Longer Lengths (non- standard) 14.5 – 29.3m

Shorter Lengths (non- standard) Below 1.8m

Note: Additional costs and transport restrictions may apply for non-standard lengths. All lengths may change for export (outside of the UK).

Dimensions, Weight & Thermal Performance

| Core Thickness (mm) | 40 | 53 | 60 | 73 | 80 | 91 | 100 | 115 | 120 | 137 | 150 |

| Overall Thickness (mm) | 71 | 84 | 91 | 104 | 111 | 122 | 131 | 146 | 151 | 168 | 181 |

| U-value (W/m²K) | 0.47 | 0.35 | 0.31 | 0.25 | 0.23 | 0.20 | 0.18 | 0.16 | 0.15 | 0.13 | 0.12 |

| Weight kg/m² 0.5/0.4 Steel | 9.8 | 10.4 | 10.6 | 11.2 | 11.4 | 11.9 | 12.2 | 12.8 | 13.0 | 13.7 | 14.2 |

| Weight kg/m² 0.7/0.5 Alum | 5.5 | 6.0 | 6.3 | 6.8 | 7.1 | 7.6 | 7.9 | 8.5 | 8.7 | 9.4 | 9.9 |

The KS1000 RW insulated wall panels have a Thermal Transmittance (U value), calculated using the method required by the Building Regulations Part L2 (England & Wales) and Building Standards Section 6 (Scotland).

Insulation Core

KS1000 RW insulated roof panels are manufactured with an HCFC, CFC and HFC free QuadCore insulation core.

Fire

The external and internal faces of the panel to be Class 0 in accordance with the Building Regulations when tested to BS 476: Part 6: 2009 and Part 7: 1997.

This QuadCore hybrid insulation core system has passed all the requirements of:

• LPS1181: 2014: Part 1: Issue 1.2, series of fire growth tests for LPCB approval and is certified to LPS 1181 Grade EXT-B.

• FM approval to FMRC 4880 & 4481 Class 1 fire classification, unlimited height.

• FM 4882 for smoke sensitive occupancy: Class 1 for interior ceiling, unlimited height.

• Reaction to fire classification according to BS EN 13501–1:2007+A1:2009: B-s1,d0.

Environmental

Kingspan Insulated Panels produced in the UK are certified to BES 6001 (Framework Standard for the Responsible Sourcing of Construction Products) ‘Very Good’. Kingspan Insulated Panels directly contribute to BREEAM/LEED credits.

Air Leakage

An air leakage rate of 3m3/hr/m2 at 50Pa or less can be achieved when using Kingspan insulated roof and wall panels.

Acoustic

Sound Reduction Index (SRI)

| Hz* | 63 | 125 | 250 | 500 | 1K | 2K | 4K | 8K |

| SRI (dB) | 20 | 18 | 20 | 24 | 20 | 29 | 39 | 47 |

* Frequency The KS1000 RW insulated roof panel has a single figure weighted sound reduction Rw = 25dB.

Biological

Kingspan panels are normally immune to attack from mould, fungi, mildew and vermin. No urea formaldehyde is used in the construction, and the panels are not considered deleterious

Materials

Substrate

▪ Kingspan XL Forté, Kingspan Spectrum, Kingspan AQUAsafe, Kingspan AQUAsafe55 and Kingspan CLEANsafe: Metallic protected steel to BS EN 10346:2015.thickness 0.5mm. CLEANsafe 15: Metallic protected steel to BS EN10346:2015.thickness 0.4mm

▪ Stainless Steel: Austenitic Grade 316 stainless steel to BS EN 10088: Part 2: 2014, thickness 0.4mm.

▪ Aluminium: Please contact Kingspan envirocare Technical Services.

Coatings - External Weather Sheet

▪ Kingspan XL Forté: Consists of a multi-layer organic coating, embossed with a traditional leather-grain finish.

▪ Kingspan Spectrum: Consists of a coated semi- gloss finish with slight granular effect.

Coatings - Internal Liner Sheet

▪ Kingspan CLEANsafe 15: The coating has been developed for use as the internal lining of insulated panels. Standard colour is “bright white” with an easily cleaned surface.

▪ Kingspan AQUAsafe: The coating has been developed for use as the internal lining of insulated panels to suit high humidity internal environments.

▪ Kingspan AQUAsafe 55: The coating has been developed for use as the internal lining of insulated panels to swimming pool internal environments.

▪ Kingspan CLEANsafe 120: The coating has been developed for use as the internal lining of insulated panels where a high level of cleanliness and hygiene is required, and the panels are to be cleaned down on a regular basis.

▪ Stainless Steel: The stainless steel liner has been developed for use as the internal lining of insulated panels in buildings with a very aggressive/corrosive internal environment.

Panel End Cut Back

Standard Cut Back Eaves 75mm

Standard Cut Back Endlap 150mm

Class A Endlap 75mm

Minimum Cut Back 20mm

Maximum Cut Back 300mm

Product Tolerance

Cut to Length -5mm +5mm

Cover Width -2mm +2mm

Thickness -2mm +2mm

End Square -3mm +3mm

Handing

The KS1000 RW insulated roof panel can be manufactured in both left to right handed (LH) and right to left handed (RH).

Seals

Factory applied side & end lap weather seals.

Quality & Durability

KS1000 RW insulated roof panels are manufactured from the highest quality materials, using state of the art production equipment to rigorous quality control standards, complying with BS EN ISO 9001 standard, ensuring long term reliability and service life. The panels are also being manufactured under Environmental Management System Certification BS EN ISO 14001. Compliant to BS OHSAS 18001 Occupational Health and Safety. The KS1000RW roof panels are CE marked to BS EN 14509: 2013.

Guarantee

Kingspan Total Panel Guarantee covering the structural and thermal performance for a period of up to 40 years and Kingspan Coating Guarantee for a period of up to 40 years (subject to project specific information).

Packing

KS1000 RW insulated roof panels are stacked weather sheet to weather sheet (to minimise pack height). The top, bottom, sides and ends are protected with foam and timber packing and the entire pack is wrapped in plastic.

| Core Thickness (mm) | 40 | 53 | 60 | 73- 80 | 91 | 100-120 | 137-150 |

| No. of panels in Pack | 17 | 15 | 13 | 11 | 9 | 7 | 6 |

Note: Applies to UK pack sizes. Please contact Kingspan Technical Services for export information.

Sea Freight

Fully timber crated packs are available on projects requiring delivery by sea freight shipping, at additional costs. Alternatively, steel containers can be used. Special loading charges apply.

Delivery

All deliveries (unless indicated otherwise) are by road transport to project site. Off-loading is the responsibility of the client.

Site Installation Procedure

Site assembly instructions are available from Kingspan Technical Services.